The most common form of regenerative energy today is the braking system in a hybrid or electric car. Instead of using a mechanical brake to slow down the vehicle, electrical regeneration stores the braking energy back in the battery. Many elevators today also use regenerative energy, storing the energy when the elevator goes down, to be re-used when the elevator goes up. AltaStream has applied the same principle of electrical energy regeneration in the design of its Automated Test Equipment (ATE), specifically for helicopter transmissions.

600 HP Automated Test Stand

Existing 600 HP transmission test equipment consumes almost 500 kW of energy and needs to be permanently assembled in a large 2000 sq ft facility. AltaStream’s regenerative energy solution uses less than 70 kW of power and is fully contained in a mobile oversized container (occupying about 400 sq. ft). The transmission is easily loaded using a custom built electrical hoist. Once connected to the stand, the transmission test is fully automated, including a customized report detailing the test results. AltaStream’s test stand utilizes state of the art motor drives, along with proprietary controls to achieve over 80% electrical energy regeneration, with a high degree of accuracy and repeatability. For our customers this translates to lower energy costs, better space utilization, and more transmissions tested due to increased equipment reliability, and single button automation. Operator and equipment safety is ensured with a separate control room, equipment door sensors, tool storage sensors, transmission type sensors, a tri-light, and sophisticated monitoring of all critical transmission and motor parameters. A window in the control room partition, and 4 high resolution video cameras allow operators real time viewing of the transmission while a test is in progress.

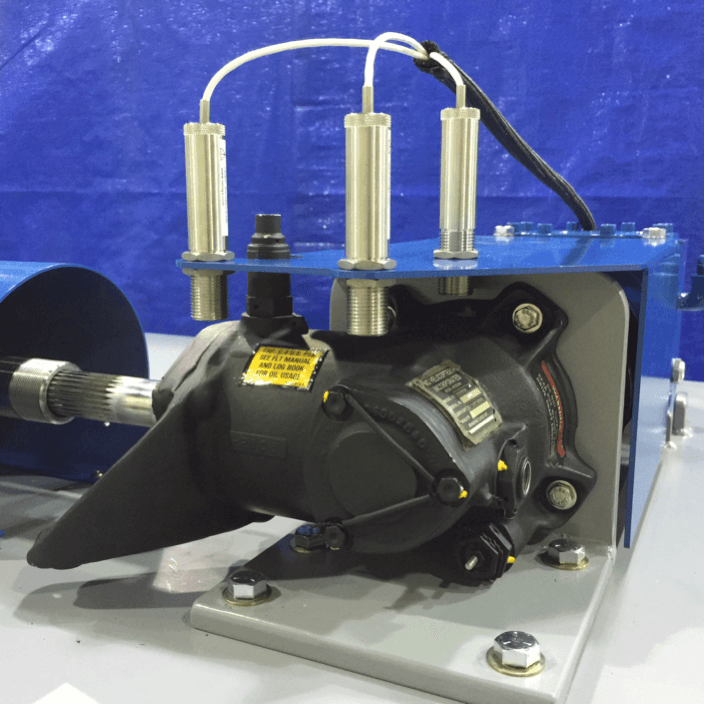

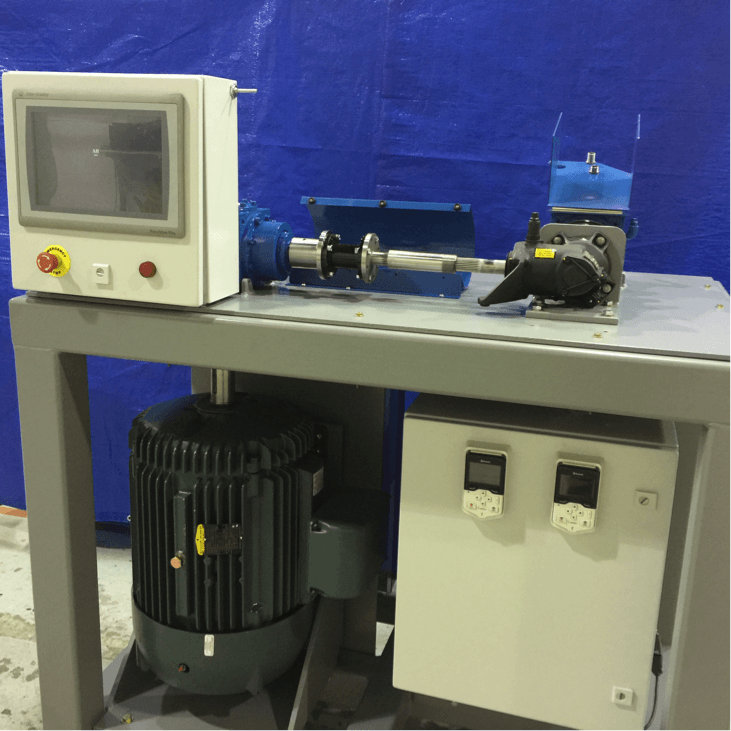

40 HP Automated Test Stand

By utilizing regenerative electrical energy in the design of our 40 HP Transmission Test Stand, AltaStream was able to develop a fully automated solution that occupies less space than a typical office desk. State of the art motor drives, and proprietary controls provide almost 85% regeneration, and full ‘Single Button’ automation. Using our unique spline gear adapters, different transmissions can be loaded or unload in just a couple of minutes. Contactless temperature probes measure all critical temperatures of the transmission. An intuitive user interface and a large 12” touch screen makes it easy to set up and run tests. Customized reports provide the operator with details of the test results. Operator and equipment safety is achieved through the use of hinged guards over rotating parts, and monitoring of all critical transmission and motor parameters.